Introduction

In today’s interconnected world, electrical safety is more critical than ever—especially in power transmission and distribution systems, industrial plants, and data centers. One often overlooked yet crucial aspect of electrical safety is grounding. Grounding ensures that in the event of a fault, excess current safely flows into the earth, protecting both people and equipment. But what happens when the grounding system itself becomes compromised?

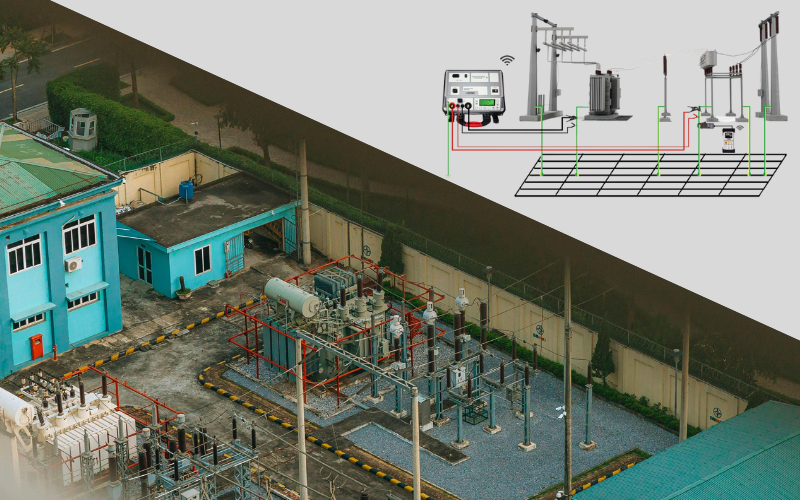

This is where Smart Grounding Monitoring Systems (SGMS) come into play. By continuously monitoring the integrity and performance of grounding systems, these intelligent solutions help prevent hazards, ensure compliance, and support proactive maintenance.

What Is a Smart Grounding Monitoring System?

A Smart Grounding Monitoring System is an automated, sensor-based technology designed to continuously measure and evaluate the health of a facility’s grounding network. Unlike traditional methods—which rely on periodic manual testing—SGMS provides real-time data on ground resistance, current leakage, voltage potential, and other key parameters.

Why Grounding Needs Monitoring

Grounding systems can degrade over time due to:

- Corrosion of electrodes or conductors

- Mechanical damage or disconnections

- Soil condition changes (moisture, temperature, chemical composition)

- Unauthorized modifications or theft of grounding materials

A compromised ground system can result in:

- Equipment damage due to poor fault dissipation

- Increased risk of electric shock or fire

- Communication disruptions due to electromagnetic interference

- Non-compliance with safety standards (e.g., IEEE, IEC, NEC)

How Smart Grounding Monitoring Works

Smart Grounding Monitoring Systems typically consist of the following components:

1. Sensors and Probes

-Measure ground resistance, leakage current, and touch/step voltages.

-Often placed at key grounding points (ground rods, grids, transformers, panels).

2. Data Acquisition Units (DAUs)

-Collect data from multiple sensors.

-Interface with local or cloud-based servers.

3. Analytics and Diagnostics Engine

-Processes real-time data.

-Detects anomalies, trends, and potential failures.

4. Communication Interface

-Supports protocols like Modbus, IEC 61850, or DNP3.

-Allows remote monitoring via SCADA, HMI, or cloud dashboards.

5. Alarming & Reporting Tools

-Notify operators of threshold breaches via SMS, email, or alarms.

-Generate reports for compliance audits and maintenance planning.

Key Features

- 24/7 real-time monitoring

- Predictive analytics for fault detection

- Remote diagnostics and troubleshooting

- Integration with SCADA and

BMS systems

- Event logging and historical

trending

Applications

Smart

Grounding Monitoring is vital in sectors like:

- Electrical substations – Ensures safety and fault

clearing efficiency

- Telecommunication towers – Prevents signal

disruption due to poor grounding

- Data centers – Protects sensitive

equipment from voltage surges

- Hospitals and laboratories – Enhances life safety in

critical environments

- Oil & gas facilities – Reduces explosion risks

in hazardous zones

Benefits

✅ Enhanced Safety

Automatically

alerts when grounding is compromised, reducing electrocution and fire risks.

✅ Operational Continuity

Prevents

unexpected equipment failures and downtime.

✅ Regulatory Compliance

Helps

meet standards such as IEEE 80, NEC 250, IEC 60364, and NESC.

✅ Cost-Efficiency

Minimizes

manual inspections and unplanned maintenance costs.

✅ Asset Protection

Protects

infrastructure from transient overvoltages and lightning surges.

Challenges and Considerations

While

Smart Grounding Monitoring offers clear benefits, deployment must consider:

- Installation complexity – Especially in

retrofitting older facilities.

- Cost of initial setup – Higher upfront but offset

by long-term savings.

- Environmental conditions – Sensors must withstand

harsh or corrosive environments.

- Cybersecurity – Secure communication

protocols are a must for remote monitoring.

Installation

Installing a Smart Grounding Monitoring System involves:

• Site Assessment – Identify grounding points and evaluate

soil and system conditions.

• Sensor Deployment – Install probes at key locations like

ground rods and panels.

• System Integration – Connect sensors to DAUs and interface

with SCADA or cloud platforms.

• Testing & Calibration – Verify sensor accuracy and set

threshold parameters.

• Training & Handover – Educate personnel on monitoring

tools and reporting procedures.

A streamlined installation ensures reliable performance and long-term safety

benefits.

Future Trends

As IoT,

AI, and 5G technologies evolve, Smart Grounding Monitoring Systems are

becoming:

- More affordable and accessible

- AI-driven for advanced predictive

maintenance

- Cloud-enabled for global visibility and

analytics

- Integrated with digital twin models

for real-time simulation

Conclusion

Smart

Grounding Monitoring Systems represent the future of electrical safety. By

transforming passive grounding networks into intelligent, self-monitoring

systems, they enable proactive maintenance, enhance reliability, and ensure

that when faults occur, the grounding system is ready to protect.