In the

modern world where energy efficiency and sustainability are paramount, Amorphous

Metal Transformers (AMTs) are emerging as a key solution for reducing

transmission and distribution losses. But what makes them different from

conventional transformers, and why are they gaining momentum globally? Let’s

dive into the world of AMTs and explore their construction, advantages,

applications, and future potential.

What Are Amorphous Metal Transformers?

Amorphous

Metal Transformers are a type of distribution transformer that use amorphous

metal cores instead of conventional crystalline silicon steel. These cores

are made from a metallic glass — a non-crystalline alloy (usually

iron-based) — which drastically reduces core losses.

Unlike

traditional grain-oriented silicon steel, amorphous metal has a disordered

atomic structure, which leads to lower magnetic hysteresis and eddy current

losses.

Construction of AMTs

While

AMTs have a similar outer appearance and basic design to conventional

transformers, their core material sets them apart:

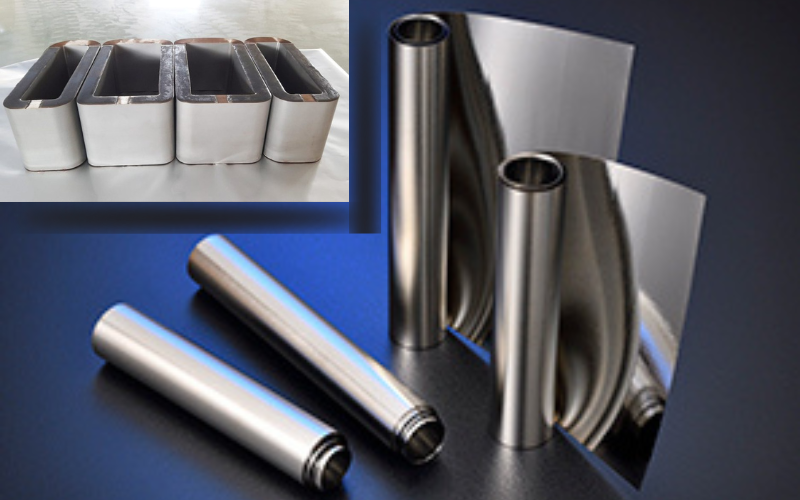

- Core Material: Amorphous metal ribbon

(thin and flexible, about 25 microns thick)

- Winding: Copper or aluminum

conductors

- Insulation: Standard insulation

materials like paper or epoxy

- Tank and Oil: Standard transformer oil

and sealed tank to prevent moisture ingress

Key Advantages of AMTs

- Lower No-Load Losses (Core Losses)

AMTs typically offer 60-70% reduction in no-load losses compared to silicon steel transformers. - Enhanced Energy Efficiency

Reduced losses translate to less electricity wastage — crucial for utilities aiming to reduce their carbon footprint. - Cooler Operation

Lower losses mean less heat generation, reducing the burden on cooling systems. - Cost Savings Over Time

Although the initial cost is slightly higher, the lifetime energy savings make them more economical in the long run. - Longer Life Expectancy

Lower operating temperatures and improved thermal performance lead to extended transformer life.

Limitations and Challenges

Despite

their many benefits, AMTs come with a few drawbacks:

- Higher Initial Cost

The amorphous metal core is more expensive to manufacture and handle. - Mechanical Fragility

The thin, brittle nature of amorphous metal ribbons demands careful handling during manufacturing. - Larger Size and Weight

To achieve the same power rating, AMTs may be bulkier than conventional units.

Applications of AMTs

Amorphous

Metal Transformers are ideal for:

- Rural and urban distribution

networks

- Renewable energy integration

(solar, wind)

- Green buildings and smart

cities

- Utilities aiming for

energy-efficient infrastructure

Countries

like Japan, China, and India are aggressively deploying AMTs under energy

conservation initiatives.

Future Outlook

With

increasing global emphasis on reducing transmission and distribution losses,

AMTs are expected to play a pivotal role. Government policies, energy

conservation codes, and carbon reduction targets will likely drive wider

adoption of AMTs, especially in developing nations with aging grid

infrastructure.